Production slitting lines for metal coils in the city Lubbock

The company "MetalWare - Lubbock" manufactures equipment for the processing of flat steel products - slitting lines for metal coils.

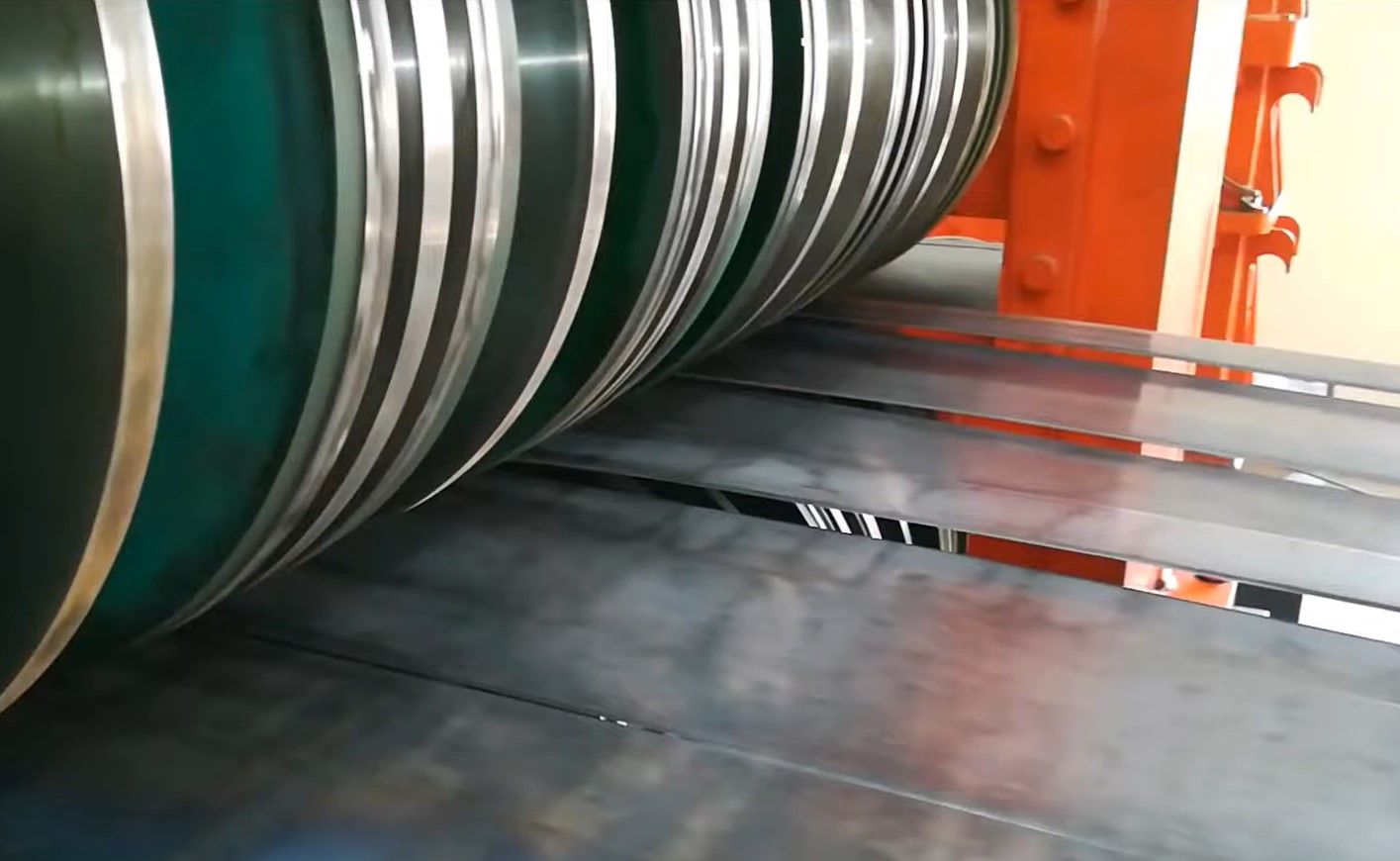

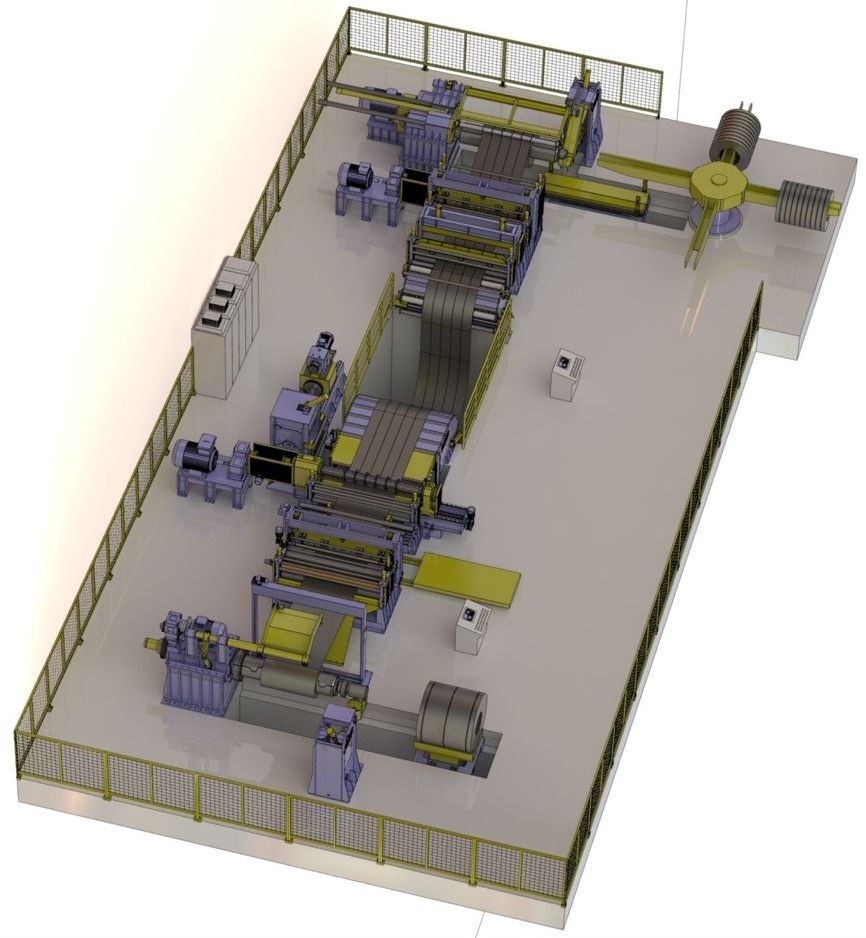

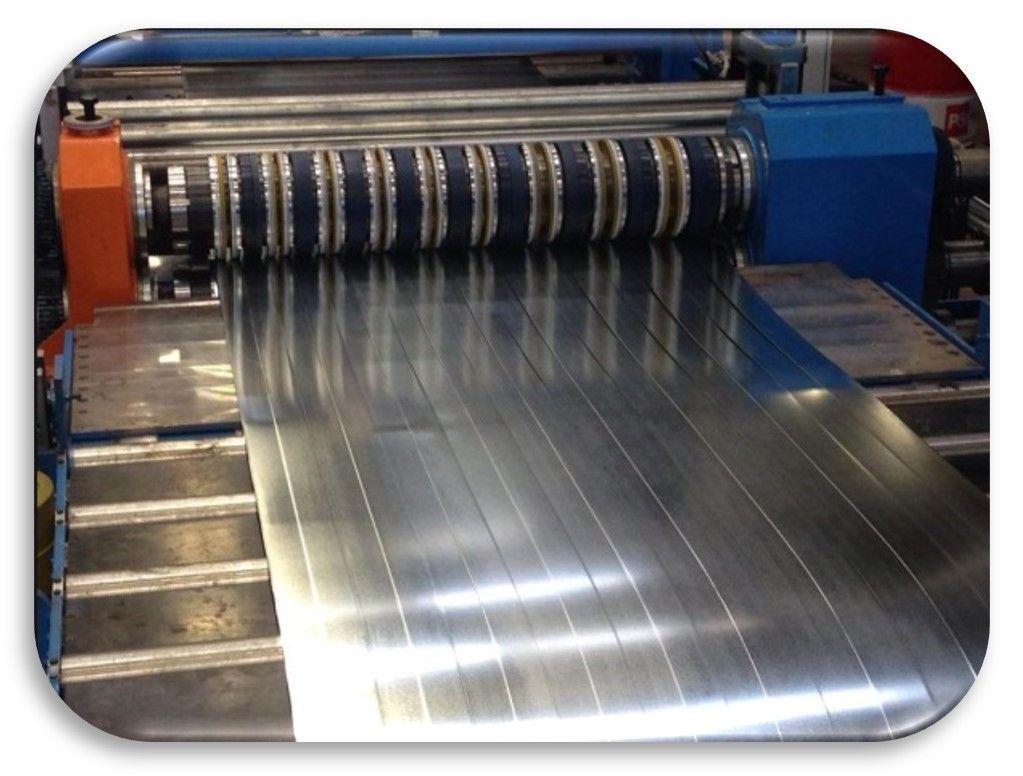

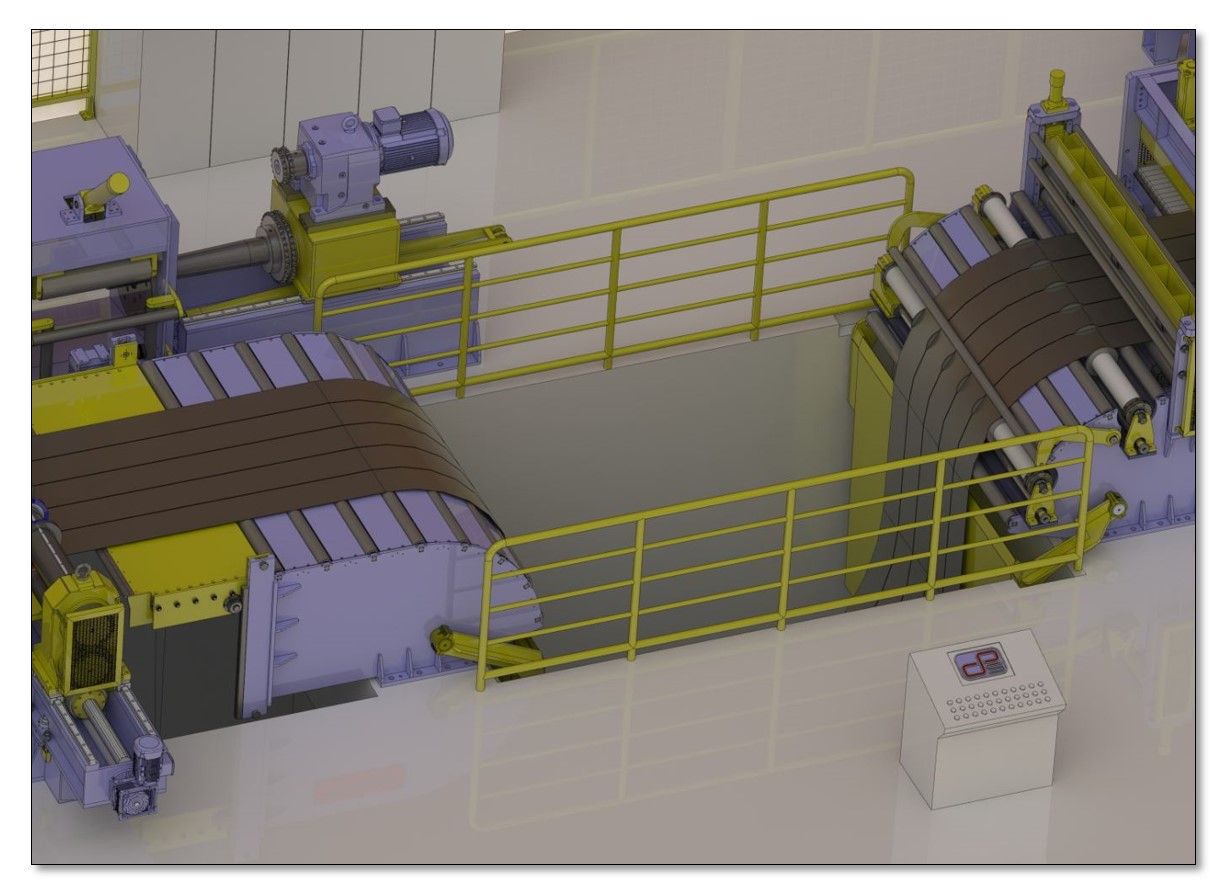

These lines are designed for unwinding coils, cutting the coils into strips with circular slitting knives placed at certain intervals, and rolling these strips into a roll.

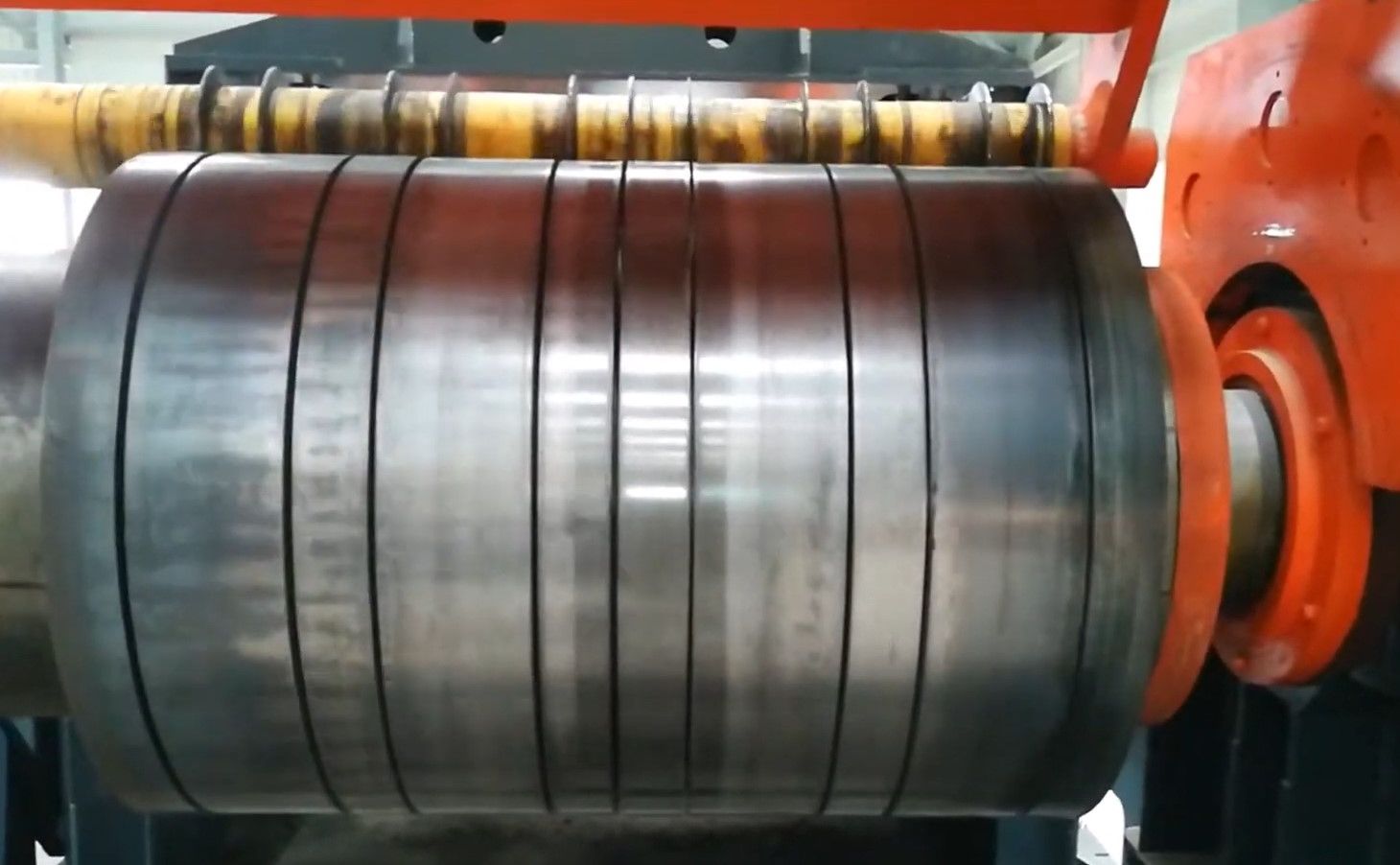

Slitting lines provide high dimensional accuracy of the resulting strip from cold-rolled and hot-rolled carbon steel, galvanized, stainless steel, aluminum, brass, copper and various special alloy steels of various widths and weights in the thickness range from 0.3 mm to 14 mm.

The width of the flat steel slitting lines that we offer for sale in the city Lubbock ranges from 500 to 2250 mm.

The productivity of the slitting lines that we offer for sale in Lubbock is from 5 to 40 tons per shift.

Our company supplies from Lubbock flat steel processing equipment - metal coil slitting lines and provides excellent engineering services.

We strongly believe that our experience and knowledge will contribute to the sustainable development of your company in the steel market.

MetalWare-Lubbock experienced team has been manufacturing turnkey sheet metal processing lines for over 30 years. We export our products to many countries around the world.

MetalWare-Lubbock shares its experience with all its customers, offering the most efficient and effective solutions for machinery supply, consulting, site selection, basic construction, employee training, line installation and operation assistance.

MetalWare-Lubbock supports its Lubbock customers so that you always feel confident while operating the lines we supply.

We carry out after-sales and maintenance services for the metal coil slitting lines we supply, as well as provide spare parts to make your work as efficient as possible.

The standard equipment of flat steel slitting lines that our company offers for sale to customers in Lubbock includes:

- installation for loading a roll;

- unwinding machine (one head);

- clamping machine with guillotine;

- slitting machine;

- baling press for scrap;

- input-output group compensator;

- installation of a tension of tapes;

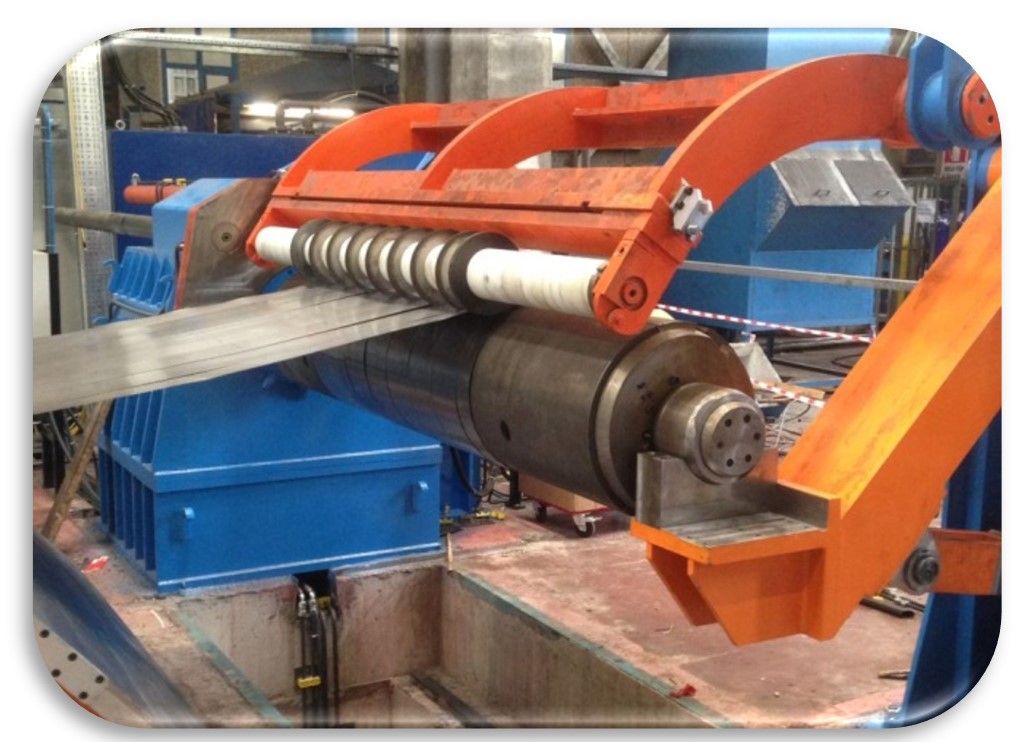

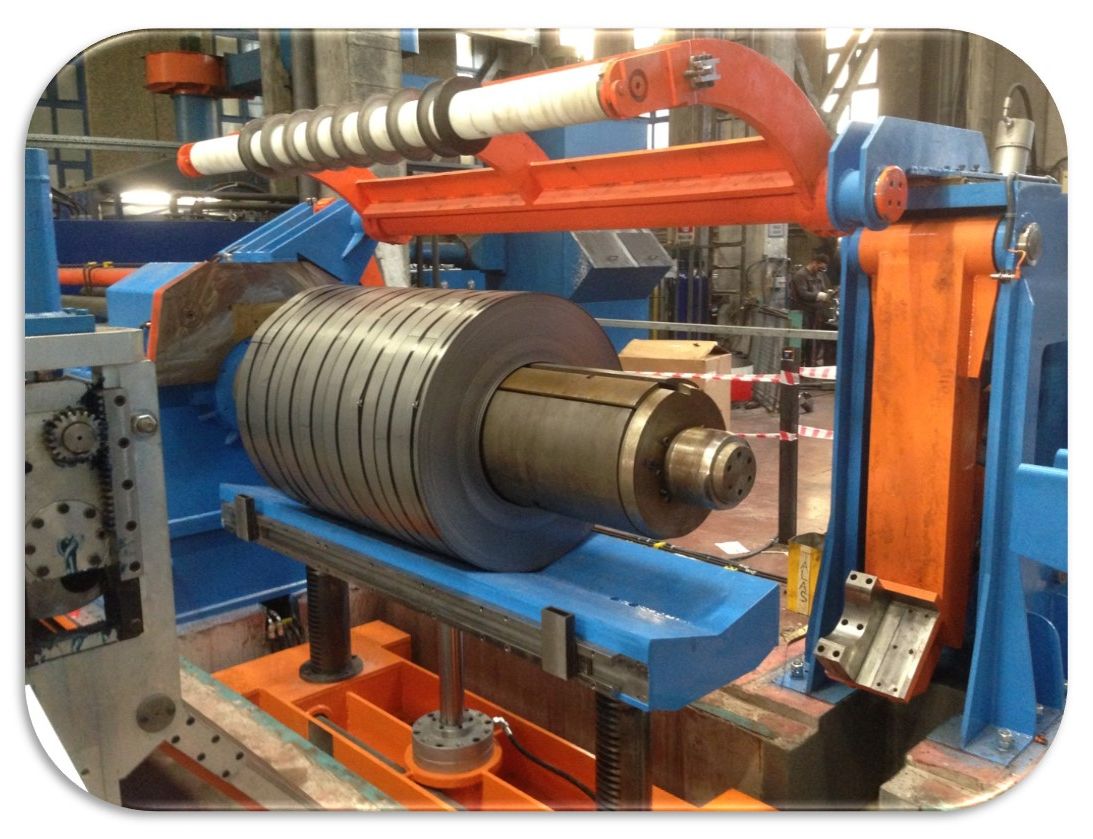

- winding machine;

- device for transporting rolls;

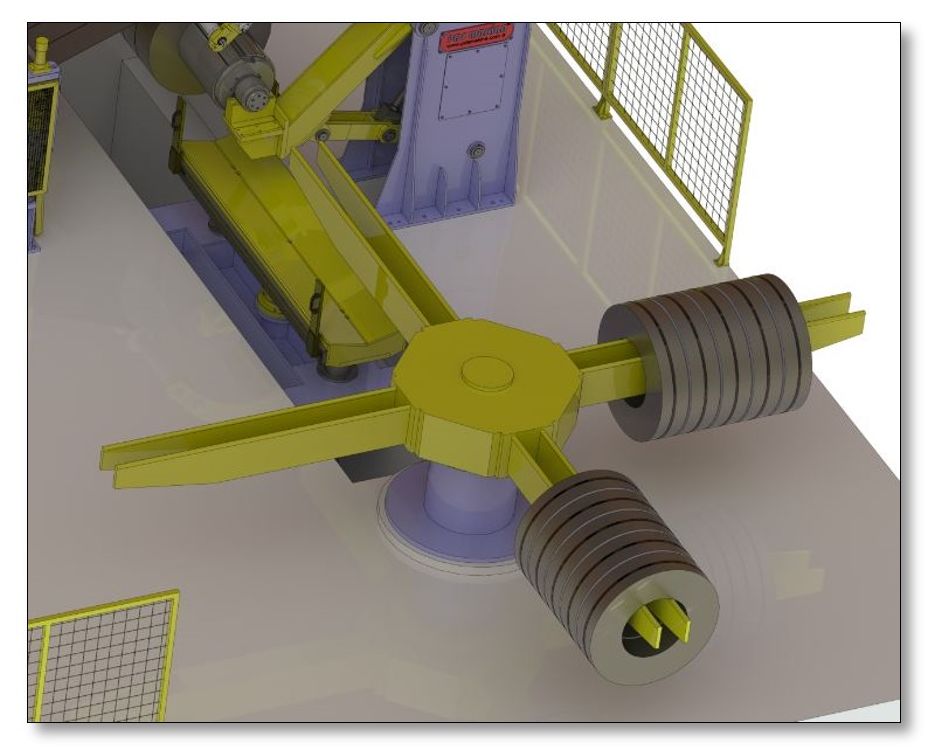

- turnstile;

- hydraulic system;

- electrical equipment and automated control system;

- installation, commissioning and training of personnel from Lubbock to work on our production lines.

How to order a flat steel slitting line with delivery and installation in Lubbock

You can order a flat steel slitting line from 5 to 40 tons per shift with delivery and installation in Lubbock.

To order a slitting line for flat steel products from 5 to 40 tons per shift with delivery and installation in Lubbock, you need to send an application using the feedback form (LINK) and our best specialist in the manufacture of metal-cutting equipment in Lubbock will contact you as soon as possible - to clarify the details of the application.

Feedback form for ordering a flat steel slitting line in Lubbock